How to reduce oil sands tailings pond area by 80%.

Suncor is an integrated energy company which pioneered the world’s first commercially successful oil sands operation in 1967 near Fort McMurray, northeastern Alberta. Suncor recovers bitumen from oil sand and upgrades it to refinery-ready crude oil, which eventually gets processed into gas and diesel fuel.

The TFT Tailings Pump Barges project, detailed on our Oil Sands Portfolio webpage, was implemented to provide a cost effective solution for the initial phase of the pond’s life. This project addressed the modifications required for the next operating phase at increased pond elevation.

BUSINESS PROBLEM SOLVED

In order to fulfill Alberta ERCB Directive 74, Tailings Reductions Operations (TRO) has been implemented. The implementation of this TRO strategy is expected to reduce the number of tailings ponds at its present mine site from eight to just one, shrinking the total land area covered by the pond by approximately 80%. Part of the overall RTO plan was to deposit Regular Tails (RT) into a sand dump; the Thin Fine Tails (TFT) runoff would then be transported and processed.

TECHNICAL PROBLEM SOLVED

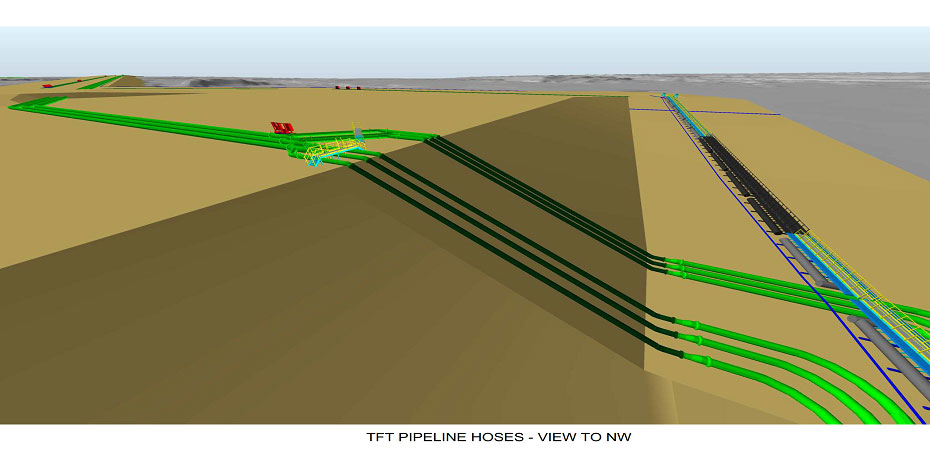

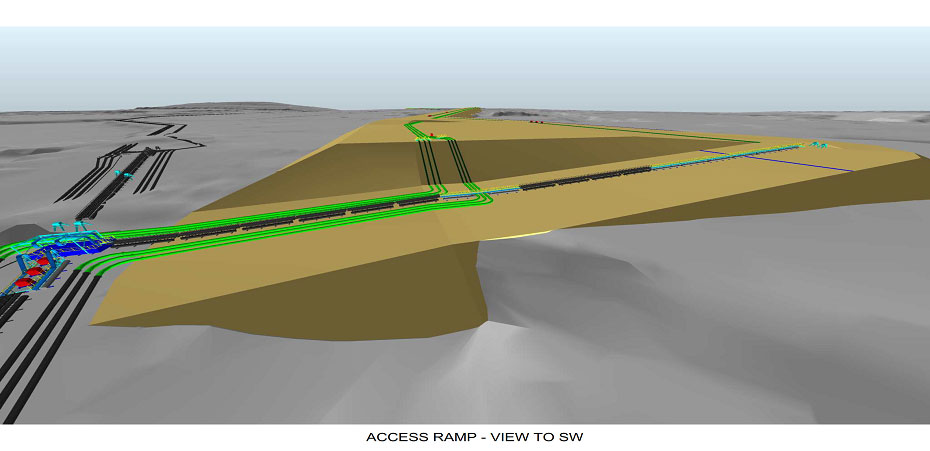

Design the next phase of the TFT pump barge, floating walkway, and piping system that must be developed to accommodate the rising pond levels beyond the operating limit of the initial phase floating walkway configuration. The design included a Temporary Pier in order to modify the Sand Placement Area 8 to allow for continuous access to the pond while it operates at pond levels of 316-325 meters.

WHAT WE DID

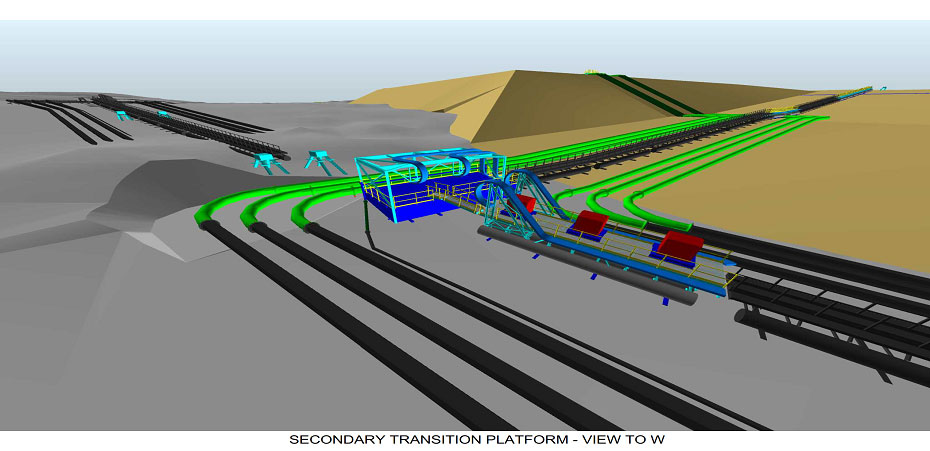

The project included extension of the existing walkway retreat ramp to accommodate the expected pond rise; marine design of modular floating transition platform accommodating barge and walkway anchor lines and phased relocation plan for TFT pumping barges; civil design required to construct the TFT retreat ramp and earthen Temporary Pad and Pier to contain the TFT pond rise; modification of existing and design of 6 new TFT DHPE lines and overland slurry pipelines; design modification to floating TFT and pump glandwater pipelines; revision to existing barge anchoring system to allow relocation to deeper area of pond; 8kV electrical trailing cable and fibre optic cable layouts and support; instrumentation design and heat tracing of pipeline automatic valves;

It was compulsory that all design aspects operated reliably in the harsh climatic conditions and remote location of the tailings pond. The project design considered the risk factors of potential sanding in of walkways, floating pipelines, and barges; minimal acceptable system downtime in the event of a failure due to fluid freezing; pipelines and cable layout and support design that would accommodate movement between walkway sections.

The construction plan needed to ensure that all design components were integrated into the existing system and brought online within the limited shutdown timeframes available with no sacrifice in production rates.

PROJECT LIFECYCLE SERVICES USED

| √ | Opportunity |

|

| √ | Definition |

|

| √ | Design |

|

| Fabrication | ||

| √ | Construction |

|

| √ | Start Up |

|

| √ | In Service |

|