How to extract MFT from ever deepening tailings pond

Suncor is an integrated energy company which pioneered the world’s first commercially successful oil sands operation in 1967 near Fort McMurray, northeastern Alberta. Suncor recovers bitumen from oil sand and upgrades it to refinery-ready crude oil, which eventually gets processed into gas and diesel fuel.

Suncor’s mining and in situ leases cover over 1,800 square km and contain nearly 13 billion barrels of bitumen resources. The company has 2,300 employees working on oil sands projects. Our project with them ran from 2010-2013.

BUSINESS PROBLEM SOLVED

Extract MFT (mature fine tailings) to meet Directive 74. (Directive 74 dictates percentage of dry tailings allowed at a mine site) The extraction of MFT also allows for increased storage capacity of the pond and balance storage.

TECHNICAL PROBLEM SOLVED

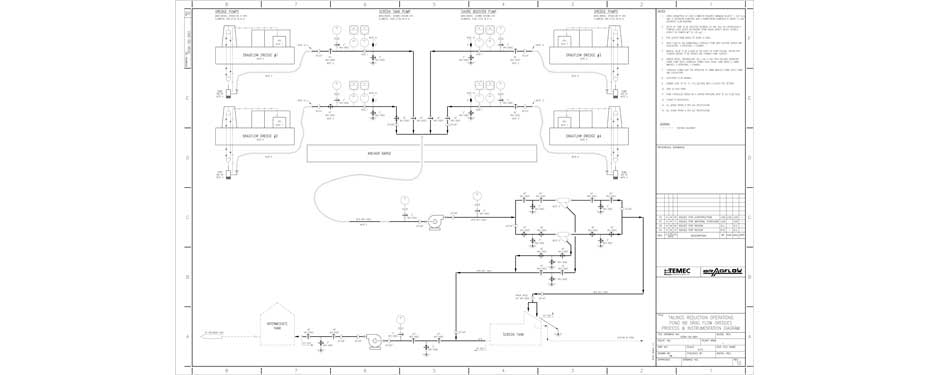

Extract MFT from ever-deepening tailings pond with layers of water and TFT (thin fine tailings) on top. Because of the depth of the Suncor pond and the fact that they needed to extract tailings from beneath the surface, typical ladder dredges wouldn’t work. Drag flow pumps (which can work up to 100m below the water’s surface) were needed.

WHAT WE DID

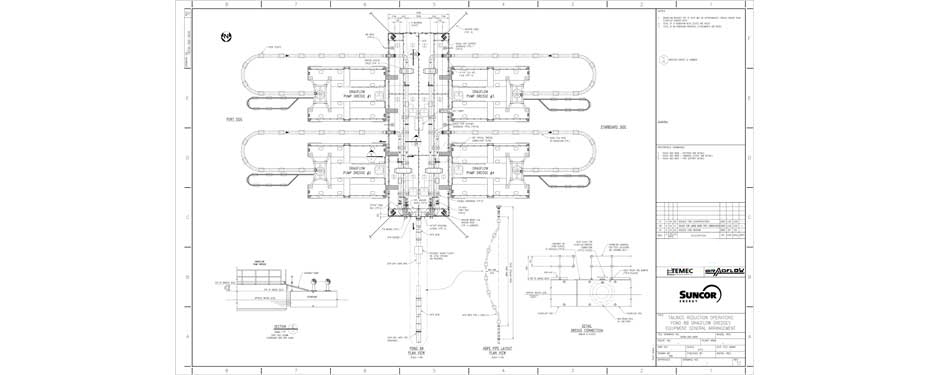

Deep-extraction drag flow pump barges can only process 1,000 m3 of fluid per hour; yet, the storage and slurry transfer-processing requirements at this site were 4,000 m3 of fluid per hour. TEMEC designed a system where four barges were tied together, supported by an integrated platform with a common discharge line. Pumps, which weigh 7,000 kilograms, hung beneath the platform surface. Other integrated features meant that maintenance and piping operator needs were less, thus saving money on human resources. Less maintenance also translated into less risk.

PROJECT LIFECYCLE SERVICES USED

| √ | Opportunity |

|

| √ | Definition |

|

| √ | Design |

|

| Fabrication | ||

| Construction | ||

| Start Up | ||

| In Service |