Fan electric power costs cut in half. Reliability issues and boiler downtime dramatically reduced.

Daishowa-Marubeni International (DMI) owns and operates the Peace River Pulp Division (PRPD) mill, located in Peace River, Alberta. PRPD produces premium hardwood (aspen) and softwood fully bleached kraft pulp in campaigns. Our project with them resulted in cutting costs of Fan electric power in half which is an annual power savings of 1,565 MWh. Also, the previous reliability issues and associated boiler downtime was dramatically reduced.

BUSINESS PROBLEM SOLVED

Fan electric power costs cut in half: annual power saving 1,565 MWh. Previous reliability issues and associated boiler downtime dramatically reduced.

TECHNICAL PROBLEM SOLVED

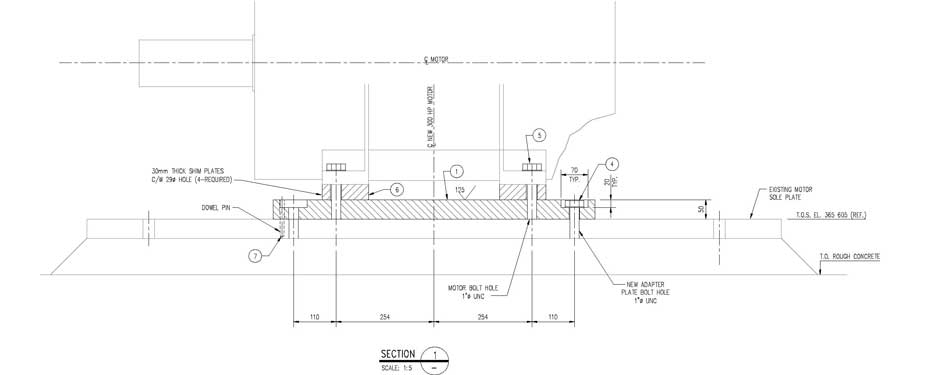

Analysis of fan performance at various speeds using affinity laws. Special motor adapter plates developed to permit rapid installation of new induction motor during a short outage with no hot work or grouting. Downstream ductwork losses verified to confirm viability of new operating speed.

WHAT WE DID

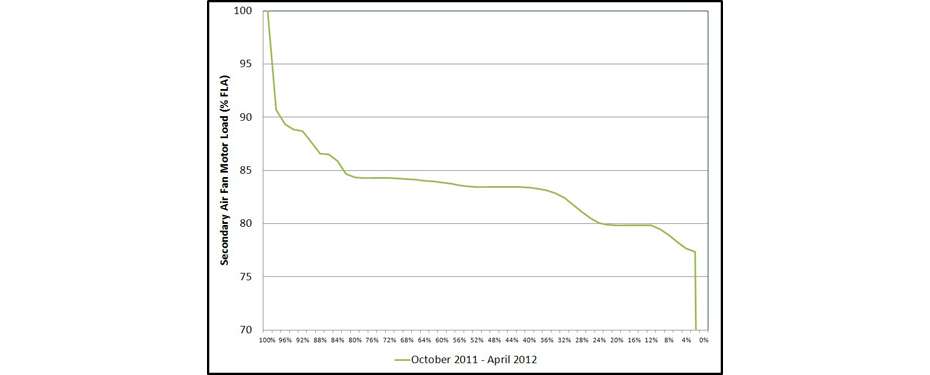

During the engineering for a large boiler upgrade, it became clear that the existing boiler secondary air fan was significantly oversized for its new service. The existing fan motor was 1,000 hp, 1180 rpm and the average load was 50 percent. Recognizing a potential business opportunity, affinity law and duct pressure drop calculations were undertaken to estimate the potential power savings at a variety of new fan speeds. The calculations indicated that replacing the motor with a fixed speed 300 hp, 900 rpm unit would offer a significant power reduction while still allowing the fan to provide the airflow and pressure required for the upgraded boiler, even under boiler purge conditions. The secondary air fan “downgrade” was added to the scope of the overall boiler upgrade.

Special adapter plates were designed to permit the rapid installation of the new motor on the existing base without any hot work, grouting or concrete work, and without sacrificing the strength required to withstand the maximum motor torque.

The new motor was installed during an outage in September 2011. The median fan power after the motor downgrade was found to be 83.4 percent of 300 hp. This represents an annual power reduction of 1,565 MWh which translates into savings of $100,000 per year. Another advantage of the reduced fan speed is that the chronic fan reliability issues observed prior to the installation of the new motor have virtually disappeared.

PROJECT LIFECYCLE SERVICES USED

| √ | Opportunity |

|

| √ | Definition |

|

| √ | Design |

|

| Fabrication | ||

| √ | Construction |

|

| √ | Start Up |

|

| √ | In Service |

|