How to analyze pressure piping systems to ensure safety and compliance with provincial regulatory authorities.

Fraser Valley Refrigeration (FVR) is a Vancouver Lower Mainland contractor whose work includes turnkey design-build services for commercial refrigeration systems. Temec has worked with FVR extensively over many years to provide pipe stress analysis and BCSA pipe registration services.

BUSINESS PROBLEM SOLVED

In accordance with the BC Power Engineers, Boiler, and Refrigeration Safety Regulations, all pressure equipment must be registered through the BC Safety Authority prior to commissioning.

TECHNICAL PROBLEM SOLVED

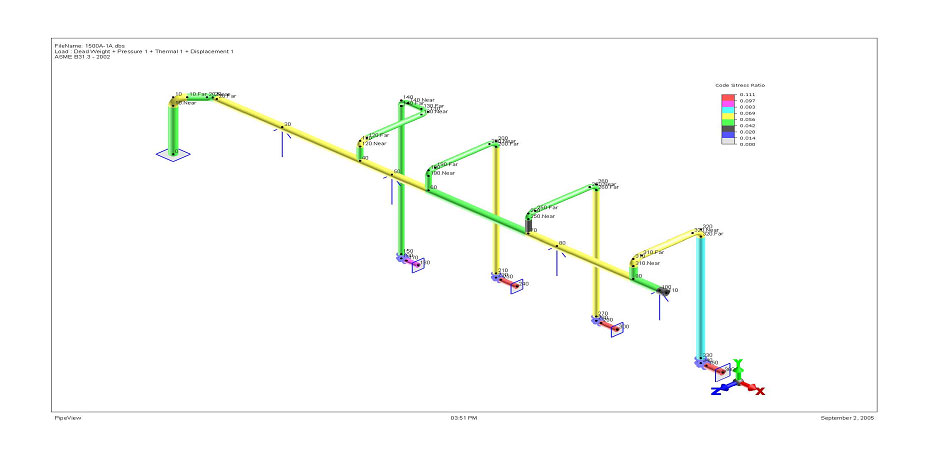

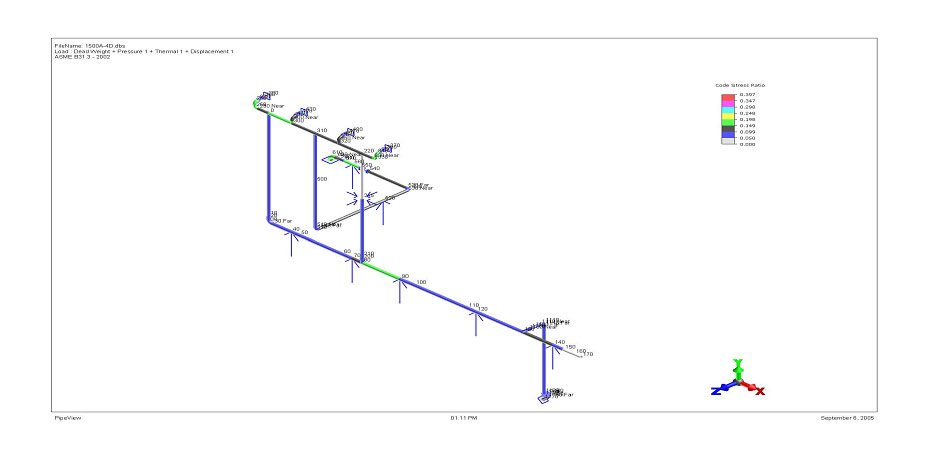

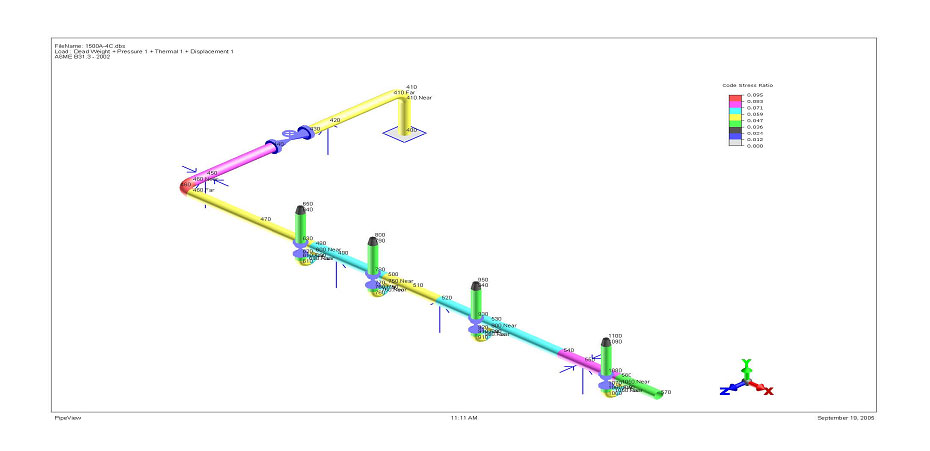

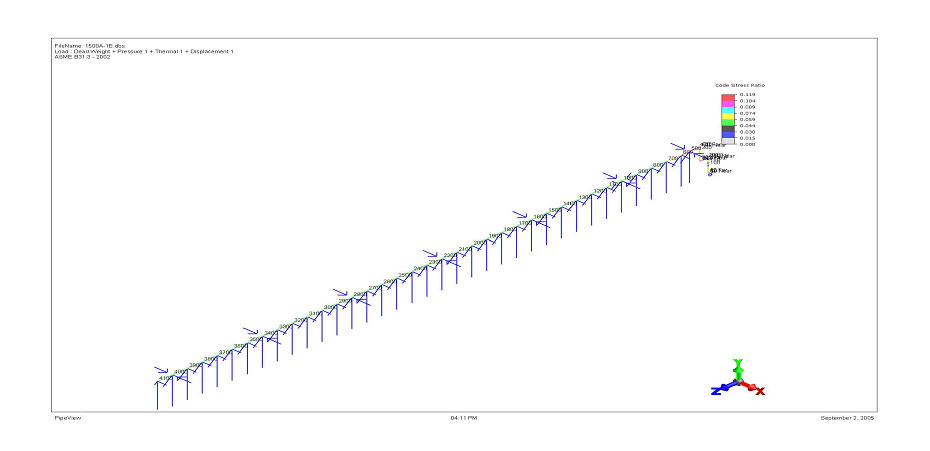

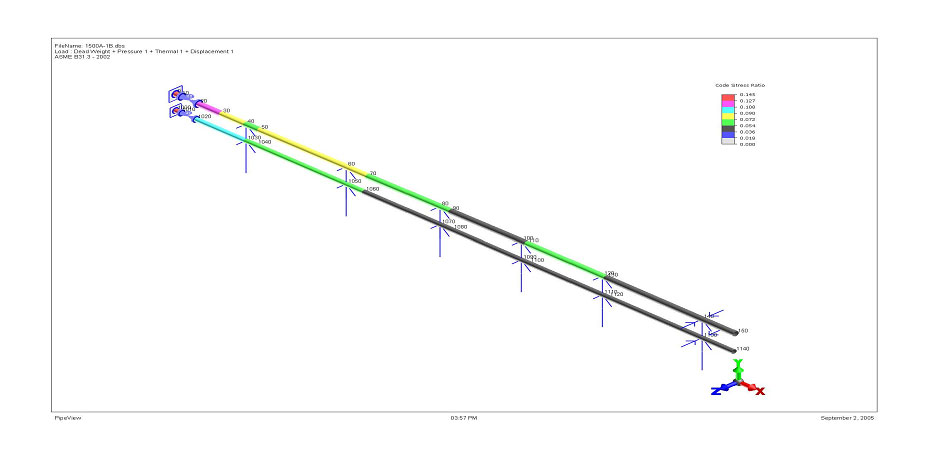

The refrigeration system consisted ammonia piping for: Condenser Drain, HTRS, Compressor Thermosiphon, Suction and Discharge. Each system was stress analyzed to verify that the pipe stresses imposed by loading cases, including seismic and thermal growth, pass the ASME refrigeration piping code stress allowables and BC Building Code requirements.

WHAT WE DID

Temec performed a site survey in order to generate piping isometrics to be used for stress analysis software entry. Any high stress areas were addressed with pipe support modifications or piping configuration changes as required. Temec provided structural pipe support design details that would accommodate the support loads generated in all code stress cases.

PROJECT LIFECYCLE SERVICES USED

| Opportunity | ||

| Definition | ||

| √ | Design |

|

| Fabrication | ||

| Construction | ||

| Start Up | ||

| In Service |